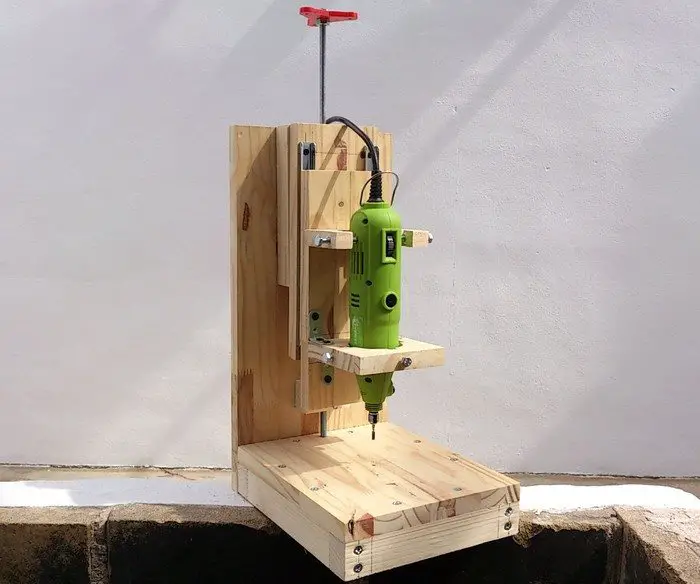

Once attached to the board they’ll provide some separation so the drill can be more far away from the board and I can work with larger materials easily. To achieve this, I cut two pieces of wood from a slat, they are 17cm tall.

DIY DREMEL DRILL PRESS INSTALL

To install the guides we need to set a separation between the board and the drill. To make it, I cut a 40cm tall board with the same width than the base, then I sand the edges. The arm: The next part of the drill press will be the arm that will hold the guides to attach the drill. NOTE: It’s not necessary to copy the dimensions to the millimeter, just get the general idea and use the materials you find more convenient.

If you remove the clamps when the holes have already been made, make some marking where two pieces come together (like circles, triangles, lines).I put some wood glue at each union to reinforce them. Once all the holes are drilled you can remove the clamp (or not if you prefer) and place the screws. With some measurements, find the center of the slat and mark the position, once you’ve found it, drill the holes, which must be slightly narrower than the screw. I’ve chosen to put them 1cm away from the edge. Once aligned, hold them together by applying pressure with the clamp to the short sides of the rectangle. Play with the position of the slats to find the optimal configuration. When you’ve finished cutting the slat, make the definitive rectangle shape with it. A minimal amount of sanding might be made afterwards. This tool keeps the blade in a vertical position, avoiding irregular cut. To avoid problems when assembling them I used a mitre and a clamp to keep the slat attached to it. The dimensions are specified on the image. To make the base, cut four pieces out of the wooden slat. The base: Sorry about the lack of pictures, but by the time I decided for this project to become a tutorial I had already finished the base. You can use it for wood, metal, plastic, or any other material.ĭo you need this drill press in your workshop?Ĭlick on any image to start the lightbox display. I cannot remember the brand name.If you need perfect holes and grooves on your project this is the tool for you, especially for small projects. While looking at drill stands, I did find one on the ‘net for the Dremel that appeared to be very well made, but it was in the $150 range. It appears that the control on the tool is a point of failure, and the added switch should reduce the wear, and it allows the speed to remain as set at the desired point. I added an “on-off” toggle switch” to the power pack (should have been included), and that makes drilling easier. I have the 12VDC “power pack” Proxxon tool. I only use the Proxxon for the drill press, as I also have a Dremel tool, that is far more versatile for other uses, and its motor develops more torque than the Proxxon. Amazon calls me “Artie G” : Customer Reviews: Proxxon 28606 MICROMOT Drill Stand MB 140/ S I reviewed this tool on the Amazon website if you care to read it.

DIY DREMEL DRILL PRESS PC

It’s reasonably well thought out, and is very accurate for drilling holes in PC boards, but with a little more thought, and some quality control improvement, it could be an excellent product. I purchased their drill stand and have had second thoughts about it.

0 kommentar(er)

0 kommentar(er)